Laminar Flow

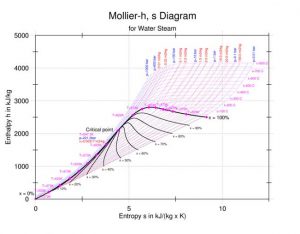

Laminar flow is a phenomenon observed in flowing fluids that manifests during the study of fluid dynamics. In general, fluid flow can be described in

Laminar flow is a phenomenon observed in flowing fluids that manifests during the study of fluid dynamics. In general, fluid flow can be described in

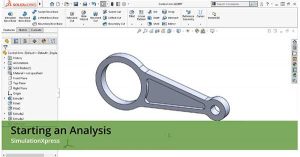

One of the best parts about SolidWorks is that you can design just about any product you can imagine. However, it isn’t always clear whether

In simplest terms, the viscosity of a fluid is the measurement of its resistance to deformation at a specified rate. For liquids, viscosity directly corresponds

While suspension bridges tend to grab the headlines there are actually seven basic types of bridges. These are beam, truss, cantilever, arch, suspension, cable stayed

Constant force springs differ from traditional helically-wound springs. They are made from pre-tensioned, high yield strips of metal (often stainless steel) as opposed to wire.

Most students don’t have a lot of money to splash around, and unfortunately, students are not eligible for a SolidWorks free trial, as that’s only

CNC fabrication involves the use of Computer Numerical Control (CNC) machines to shape and resize a block of material (known as a workpiece) by automatically

When you finally made your choice between different CAD softwares, and settled on Solidworks, you need to consider which reseller you are going to choose.

These are exciting times to be involved in engineering. The 4th Industrial Revolution (4IR or Industry 4.0 – whichever you prefer) is in full swing.

What better time than the New Year to reflect on the ups and downs of the last twelve months? Hopefully, there are many achievements and

You may have thought about or discussed the question: Which invention has saved the most lives throughout human history? The field of medicine has many

Metal 3D printers have been around for over a decade but have been out of reach for most. With the introduction of the Markforged Metal

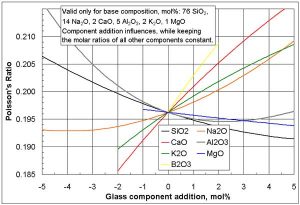

Poisson’s ratio is a value that defines the amount of contraction that occurs when something is stretched, or the amount of expansion when an object

Additive Manufacturing is gradually gaining inertia throughout the different branches of industry. However, one of the mains obstacles is the endurance and performance the parts

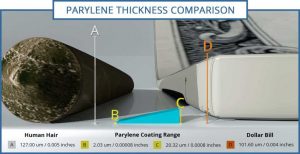

Most engineering installations and equipment are subjected to (and designed to withstand) a variety of atmospheric conditions and over a wide range of temperature, pressure,

Surgical interventions are now relying more and more on 3D printing to gain a deeper insight into complex operations and devise surgical interventions. All the

Deciding on the ideal coating for your engineering application is always a very difficult task, you need to decide on chemical, process, mechanical and component

The Venturi Effect was discovered by Italian physicist Giovanni Battista Venturi who lived between 1746 and 1822. In practice there were a number of other

The act of measuring has become an important part of our everyday lives. The need to measure and standardise has developed into the science of

Highly Accelerated Life Testing (HALT) refers to a reliability testing technique that aims to expose the weaknesses of a product. The main objective is to

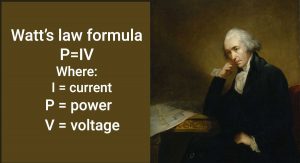

In the study of electronics, many laws and theories exist. These laws enable us to understand the workings of electric circuits and components. One such

This week Tesla unveiled their highly anticipated cyberpunk inspired Cybertruck much to the amusement of the automobile industry experts. Elon Musk presented Cybertruck as a

Burnishing is the process of rubbing metal with a small hard tool, which can be either a ball type or roller type, to compact the

Solidworks releases a new version of their software every year without fail. And every year there is an impressive lineup of new and exciting features

The best way to describe electroforming is a metal forming process used to manufacture parts using electrolyte deposition onto a model. In the manufacturing industry

Thermoforming is a plastic manufacturing process where a thermoplastic sheet is deformed into a specific shape. The process starts with the heating of a flat

Shot peening (also known as shot blasting) is a surface conditioning process carried out after various manufacturing processes. In simple terms it increases/improves the surface

As the name suggests magnetic bearings use magnetic levitation to support the rotating shafts, without directly contacting them, thus there is no friction. As we

Parkerizing is a method used on ferrous metals such as wrought iron, cast iron, steel and alloy steel, offering added protection from corrosion. This process

Electropolishing is a material removal process using an electrically powered chemical process called electrolysis. In this process the amount of material being removed is very

Out of all the materials available on the earth, only a few satisfy the design and regularity requirements for use in surgical instruments. In this

In simple terms, the melting point of steel for example, is the temperature when it starts to change from a solid state to a liquid.

Join our mailing list to get regular updates