The plasma gases include argon, hydrogen, nitrogen and mixtures, plus air and oxygen.

PAC has a higher cutting speed and produces a smaller HAZ than oxy-fuel cutting

Typical Uses:

- Engine components.

- Sheet-metal fabrication.

- Domestic appliances.

- Instrumentation devices.

- Pipes.

Examples of uses

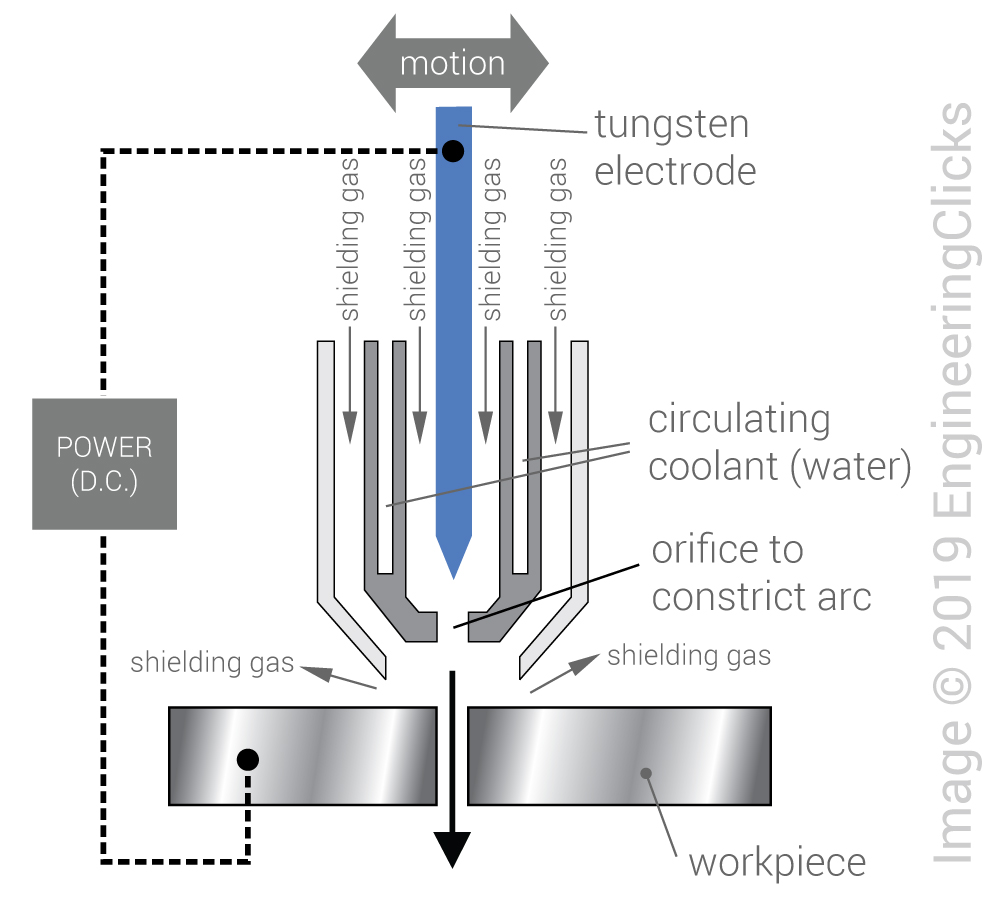

b. Example of the process during operation.

Design guidelines for Plasma Arc Cutting

- Cutting, slotting and profiling operations are common.

- The process causes a heat-affected zone (HAZ).

- As the plasma process cuts by melting, a characteristic feature is the greater degree of melting towards the top of the metal resulting in top edge rounding, poor edge squareness, or a bevel on the cut edge.

- Material thickness up to 50mm can be cut, but with heavy-duty equipment, materials up to 150mm thick can be cut.

Process variations

- PAW (Plasma-arc welding). The difference between this and cutting is that a filler rod is used. The plasma provides the melting/fusion of the base materials and rod.

- PAS (Plasma-arc spraying). Solid feedstock is melted and sprayed onto substrate to alter surface properties (e.g. wear resistance/oxidation protection).

- High Tolerance Plasma Arc cutting (HTPAC) systems are competitive with laser cutting systems because they alloy better accuracy and a smaller HAZ than conventional PAC. (HTPAC can cut metals from 0.8 to 10mm thick).

- PAG (Plasma-arc Gouging) can create blind features, typically 12mm wide and 5 to 6mm deep.

- Water shielded PAC.

Tradenames/alternative names

- HTPAC (High Tolerance Plasma Arc Cutting).

- PBM (Plasma Beam Machining).

The environment

- Produces high noise levels.

- The heat potentially causes toxic fumes. Smoke and fumes can be reduced using the water-shielded process variation.

- PAC can be used underwater.

The economics

- Typically automated.

- This is a viable alternative to TIG welding for automation. HTPAC is a viable alternative to laser cutting.

- High equipment costs. Low finishing costs. Moderate labour costs.Economical for prototyping or low production runs.

- Filters and cooling water deionisers create addition maintenance and production costs.

- The electrode and nozzle may need replacement every 2 to 8 hours depending on processing conditions.

Technical notes

- The equipment has two modes of operation:

- Melt-in fusion for reduced distortion (lower currents). This method is for welding.

- Key-hole fusion for complete penetration of material thickness (higher currents). This method is for cutting.

- The choice of gas and mixture proportions is important depending on required operating conditions.

- The operating voltage to sustain the plasma is typically 50 to 60V. The open circuit voltage needed to initiate the arc can be up to 400V DC.

- Shielding gas is argon, argon-H2 or nitrogen for the method with the tungsten electrode.